Engineering the Future with ESC: How Vinyl Sheet Piles Deliver Value, Strength, and Sustainability

- ESC Group

- Aug 15, 2025

- 8 min read

Updated: Oct 12, 2025

The Origin of Vinyl Sheet Piling

Sheet piling has been used for centuries to reinforce earthworks and prevent erosion, with early solutions made from timber and stone. The evolution of steel piling in the 20th century revolutionized heavy-duty applications—but brought with it issues like corrosion and high cost.

In the late 1900s, advances in polyvinyl chloride (PVC) technology introduced lightweight, corrosion-resistant material that could stand up to harsh marine environments. Vinyl sheet piles were born out of this innovation, offering a durable alternative with surprising benefits.

Reinventing Shoreline Protection: Vinyl Sheet Piling as a Modern Alternative

In the world of civil engineering and marine construction, material innovation is key to building structures that last. One such innovation making waves is vinyl sheet piling—a lightweight, corrosion-resistant solution that’s rapidly replacing traditional materials like steel, concrete, and wood.

Vinyl sheet piling, also known as PVC sheet piles, offers a compelling alternative to conventional materials used in bulkheads, seawalls, and cutoff walls. Unlike steel, which is prone to rust, or wood, which deteriorates under marine conditions, vinyl stands strong against the elements.

Key Advantages:

Superior Corrosion Resistance: Vinyl doesn’t oxidize when exposed to seawater, making it ideal for coastal and waterfront applications.

Marine Borer Resistance: Unlike timber, vinyl is impervious to damage from marine organisms like mollusks and crustaceans.

Lightweight and Easy to Install: Vinyl sheet piles are up to 40 times lighter than steel per square meter, simplifying transport and installation.

Aesthetic Longevity: Vinyl maintains its appearance over time—no fading, rusting, or chipping.

Eco-Friendly: No toxic coating is required, and the material is recyclable.

ESC Steel’s Vinyl Sheet Piling: Engineered for Performance

Vinyl sheet piling is increasingly used in:

Flood Protection Walls

Riverbank Stabilization

Retaining Walls for Landscaping

Chemical Containment Barriers

Jetty and Dock Construction

Its versatility and resilience make it a go-to choice for engineers and developers seeking sustainable, cost-effective solutions.

Engineered for Versatility and Strength

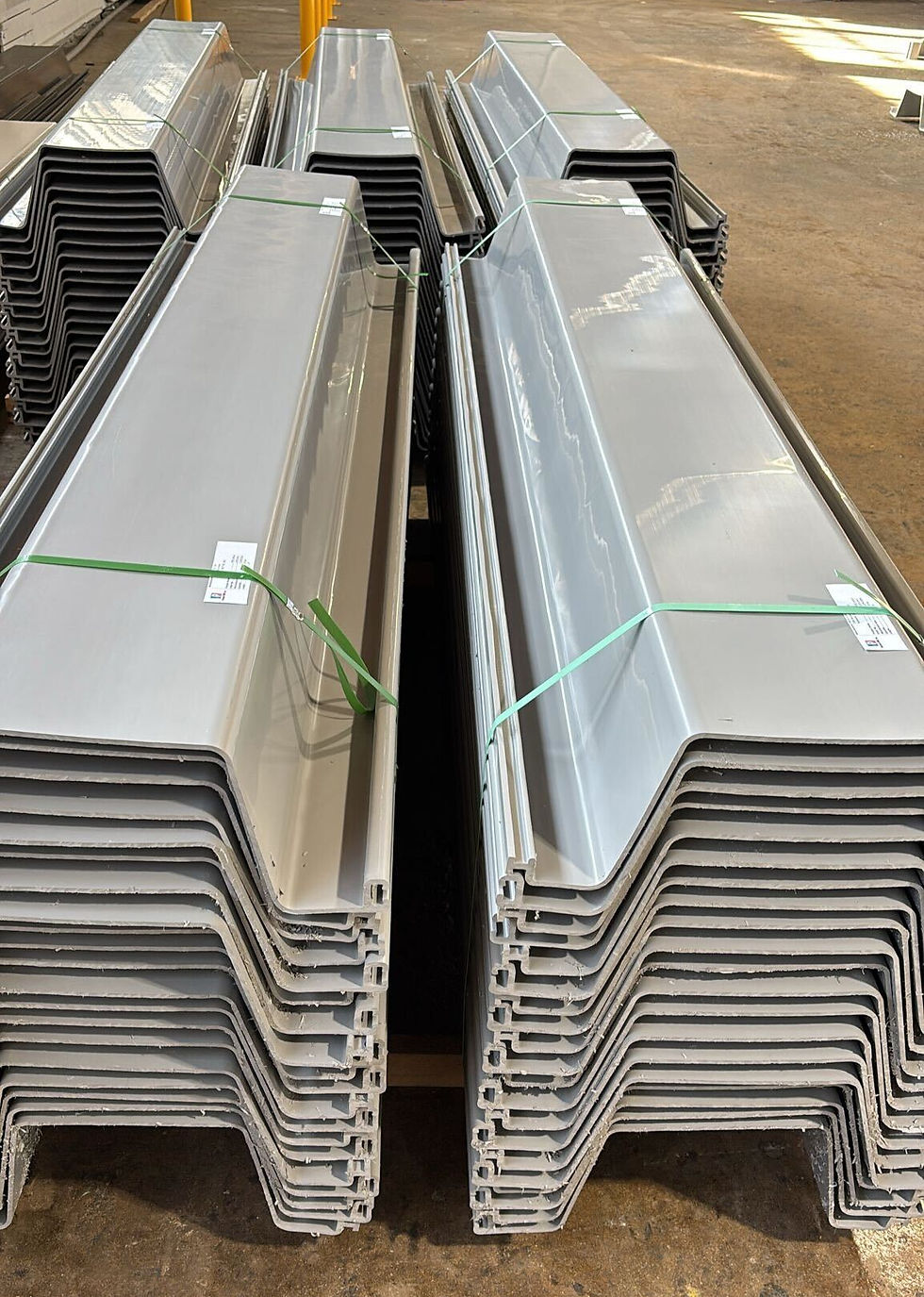

When it comes to earth retention and waterfront protection, choosing the right sheet pile profile can make all the difference. ESC Vinyl Sheet Piles offer a diverse range of profiles designed to meet the structural and environmental demands of modern construction.

Profile Variety for Every Project

Type Profiles: ESC-VZ437-10.5 Vinyl Sheet Pile - Ideal for high bending strength and deep wall applications

Box-Type Profiles: ESC-VU610-9.0 Vinyl Sheet Pile -· Hybrid Type. These are designed to fit specific, hybrid needs. They can be a combination of any of the other vinyl sheet pile types.

Omega-Type Profiles – Lightweight and easy to install, perfect for landscaping and light marine use. Designed for enhanced stiffness and water cutoff performance.

Double U and Hybrid Profiles – Engineered for flexibility and watertight interlocks ; U-shaped sheet pilings are shaped like a U and are interlocked at each end. They are commonly used as barrier walls.

PESC Box Type Vinyl Sheet Pile

PESC-24 vinyl sheet pile is a box profile that offers unmatched versatility and innovative characteristics that promote durability and excellent resistance to corrosion, impact, and ultraviolet rays. This product is designed to provide superior performance in a wide range of soil and environmental conditions, making it ideal for permanent applications. Additionally, its lightweight nature allows for easy handling and installation, reducing overall project time and labor costs. Vinyl sheet piles manufactured by Pietrucha ESC Inc. meet the following industry standards:

ASTM D8427-21: Standard Specification for Rigid Poly Vinyl Chloride (PVC) Exterior Profiles Used for Sheet Piling; USACE EM 1110-2-2502: US Army Corps of Engineers Specification for Flood Walls and other Hydraulic Retaining Walls; Other Local and National Specifications.

Each profile is manufactured with strict dimensional tolerances, ensuring consistent performance and easy installation. ESC’s vinyl sheet piles are available in various lengths, colors, and wall thicknesses to suit project-specific requirements.

Built to Last

Corrosion-resistant – No rust, even in saltwater

UV-resistant – Engineered to withstand sun exposure

Marine borer-proof – Unaffected by aquatic organisms

Eco-friendly – Made from recyclable PVC with no toxic coatings

With a design life exceeding 50 years, these profiles are trusted in applications ranging from flood protection and seawalls to retaining walls and containment barriers.

Development of Vinyl Sheet Piling

Sheet piling has long been a cornerstone of civil and marine construction. Early solutions relied on wood, concrete, and steel, each offering structural support but facing limitations—wood deteriorated in water, concrete was heavy and brittle, and steel corroded over time.

In the late 20th century, engineers turned to polyvinyl chloride (PVC) as a sustainable alternative. Vinyl sheet piling emerged as a lightweight, corrosion-resistant solution ideal for bulkheads, seawalls, and cutoff walls. Its resistance to marine borers and chemical degradation made it especially valuable in harsh environments.

Thanks to advancements in manufacturing technology, modern vinyl sheet piles now boast enhanced structural integrity, UV resistance, and longer design life—often exceeding 50 years.

One of the leaders in this innovation is ESC Steel whose vinyl sheet pile division, ESC Vinyl Pile, operates out of Statesville, North Carolina in partnership with Pietrucha ESC Inc. Over the years, ESC has evolved into an internationally certified organization with full capabilities in engineering, design, manufacturing, and construction. From its offices in North Carolina, Mexico, and Colombia, ESC coordinates vinyl sheet piling activities across North and South America, delivering cutting-edge solutions for modern infrastructure.

Key Advantages of Vinyl Sheet Piling

Vinyl sheet piling has become a preferred solution in modern construction, especially for waterfront and flood protection projects. Its unique properties offer both practical and economic benefits, making it a smart alternative to traditional materials like steel, concrete, and wood.

Vinyl doesn’t rust or degrade in saline environments, unlike steel.

ESC Vinyl Sheet Piles boast a 50+ year design life, maintaining structural integrity even in harsh marine conditions.

Environmental Friendliness

Made from recyclable PVC, vinyl sheet piles have a significantly lower environmental footprint.

ESC’s products require no toxic coating, reducing ecological impact and eliminating harmful leaching.

Ease of Installation

Vinyl panels are lightweight—up to 40 times lighter than steel per square meter, making them easier to transport and install.

ESC Vinyl Sheet Piles can be driven using compact vibrohammers or even pressed down with excavators under suitable conditions.

Noise Reduction

Installation is quieter compared to steel, which is ideal for residential or urban projects.

ESC’s precision manufacturing ensures smooth driving with minimal disruption.

Aesthetic Options

Vinyl comes in various colors and finishes, offering flexibility for landscaping and architectural integration.

ESC Vinyl Sheet Piles maintain a consistent appearance over time—no fading, rusting, or chipping.

Resistance to Marine Borers

Unlike timber, vinyl is unaffected by marine organisms such as mollusks and crustaceans, ensuring long-term durability in aquatic environments.

UV Resistance

ESC’s PVC formula includes special compounds that protect against ultraviolet degradation, preserving both strength and appearance.

Economic Benefits of Vinyl Sheet Piling

Vinyl sheet piling offers more than just structural performance—it delivers long-term savings and value across every phase of a project.

Cost Efficiency

Vinyl sheet piles are significantly lighter—up to 70% less weight than steel—which reduces transportation costs and simplifies logistics.

ESC Vinyl Sheet Piles are competitively priced per meter, offering a lower upfront investment compared to traditional materials.

Longevity

With a design life exceeding 50 years, ESC’s vinyl piles resist corrosion, marine borers, and UV degradation—minimizing maintenance and replacement costs.

Time Savings

Their lightweight nature allows for faster installation, often using compact equipment like vibrohammers or excavators, which shortens project timelines and reduces labor expenses.

Value in Infrastructure

ESC Vinyl Sheet Piles enhance shoreline stabilization, flood protection, and erosion control, helping governments and developers reduce long-term public spending on repairs and reinforcements.

Vinyl vs. Steel Sheet Piling: Economic Comparison

Category |

Vinyl Sheet Piling (ESC Vinyl Pile) | Steel Sheet Piling |

Material Cost | Lower cost per meter | Higher raw material & processing cost |

Transportation | ~70% lighter → reduced shipping expenses | Heavy, costly logistics |

Installation Cost | Lightweight → minimal equipment, faster setup | Requires skilled labor & heavy machinery |

Installation Time | Quicker installs with a vibrohammer or excavator | Longer setup due to weight & complexity |

Maintenance | No coatings needed; corrosion & borer resistant | Requires periodic coating & rust treatment |

Design Life | 50+ years of consistent performance | Variable lifespan; environmental conditions dependent |

Environmental Impact | Recyclable, low carbon footprint, non-toxic coatings | Heavier impact: coatings may be harmful |

Visual Longevity | Resists fading, rusting, and marine staining | Prone to corrosion stains and paint degradation |

Infrastructure Value | Boosts shoreline & flood resilience with reduced public spending | Effective but may require future upgrades |

Where Vinyl Sheet Piles Make a Difference: ESC’s Proven Applications

Vinyl sheet piling has become a trusted solution for projects that demand durability, corrosion resistance, and environmental responsibility. With over 35 years of experience, ESC Vinyl Pile continues to deliver innovative PVC sheet pile systems across a wide range of industries and geographies.

Marine & Waterfront Structures

ESC Vinyl Sheet Piles are ideal for bulkheads, seawalls, tide walls, breakwaters, and jetty structures. Their lightweight profile and resistance to saltwater corrosion make them a long-lasting alternative to steel and timber in coastal environments.

Flood Protection & Water Control

Used in levees, flood walls, and dam stabilization, ESC’s vinyl piles offer watertight performance with optional Eco seal gaskets for enhanced seepage resistance. They’re also effective in river diversions, pond linings, and baffle walls for water flow management

Retaining Walls & Erosion Control

Whether for landscaping, embankments, or road construction, ESC Vinyl Sheet Piles provide a clean, aesthetic finish while preventing soil loss. Their corrosion resistance and UV stability ensure long-term performance with minimal maintenance.

Cutoff & Containment Systems

ESC’s chemically inert PVC profiles are perfect for groundwater cutoffs, fluid seepage barriers, and chemical containment. The coextruded sealing membranes further improve watertightness in sensitive applications.

Case Study:

ESC Vinyl Sheet Piles Reinforce Flood Protection in Kraków, Poland

As urban development accelerates, so does the risk of flooding, especially in low-lying districts near rivers. In Kraków, Poland, frequent flood events prompted the need for a durable, watertight solution to protect residential areas. ESC Vinyl Pile stepped in with a high-performance answer.

The Challenge

Rapid urbanization had weakened embankments along the river, which were composed of loose soils and aging sandbags. Traditional materials couldn’t guarantee long-term protection or watertight integrity.

The Solution

ESC deployed Eco seal vinyl sheet piles with integrated gaskets to form a watertight barrier. These piles were driven 7 feet below ground and extended 4 feet above, reinforcing the embankment and significantly improving water retention capacity.

Impact

Enhanced flood protection for vulnerable neighborhoods

Long-term durability in mixed soil conditions

Environmentally friendly installation with minimal disruption

This project shows how ESC Vinyl Sheet Piles offer a sustainable, cost-effective alternative to steel or concrete—especially in flood-prone regions.

Conclusion: Vinyl Sheet Piling—A Smarter Future for Infrastructure

From its origins as a lightweight alternative to steel and timber, vinyl sheet piling has evolved into a cornerstone of modern construction. Its corrosion resistance, ease of installation, and environmental advantages make it a versatile solution for everything from flood protection to waterfront development.

ESC Vinyl Pile has been at the forefront of this transformation, offering high-performance PVC sheet piles with a design life exceeding 50 years. Manufactured in Europe and Asia and distributed globally, ESC’s products are engineered for strength, sustainability, and long-term value.

As industries shift toward greener, more cost-effective infrastructure, vinyl sheet piling stands out as a future-proof choice. Whether you're building seawalls, retaining walls, or containment systems, ESC Vinyl Pile delivers the durability and efficiency of today’s projects demand.

Explore ESC’s full range of vinyl sheet piling solutions at https://escvinylpile.com/ and discover how your next project can benefit from smarter materials and sustainable engineering.

Ready to Reinforce the Future?

Don’t settle for outdated materials when smarter, more sustainable alternatives are within reach. Whether you’re protecting coastlines, stabilizing landscapes, or safeguarding communities from flooding—ESC Vinyl Sheet Piles offer the durability, cost-efficiency, and environmental performance today’s projects demand.

👉 Visit https://www.escsteelphil.com/ to explore profiles, applications, and case studies. 💬 Reach out to the ESC team for expert guidance, custom solutions, or project quotes Email: philippines@escpile.com 📦 Build smarter. Build with confidence. Build with ESC